Application:Mooring,Marine,Ship

Products

hot-sale products

-

Stud Link Anchor Chain AM2 for Marine Ship

Stud Link Anchor Chain AM2 for Marine Ship -

Hot-dip galvanized Studless Fishing Chain Aquaculture

Hot-dip galvanized Studless Fishing Chain AquacultureApplication: Aquaculture, Fish farm mooring

-

AC-14 HHP Casting Steel Stockless Anchor Marine for Ship

AC-14 HHP Casting Steel Stockless Anchor Marine for ShipAC-14 anchor is a stockless HHP anchor with a wide anchor crown, thick and long flukes, and longitudinal ribs.

-

Marine ADA Aqua Drag Anchor aquaculture mooring

Marine ADA Aqua Drag Anchor aquaculture mooringADA aqua drag anchor is improved version base on generation of aqua-moor DSA anchor, yet provides better performance.

-

G2130 Shackle Bolt Bow Forged Anchor Shackle

G2130 Shackle Bolt Bow Forged Anchor ShackleApplication:Lifting accessory commonly used in industrial and construction settings.

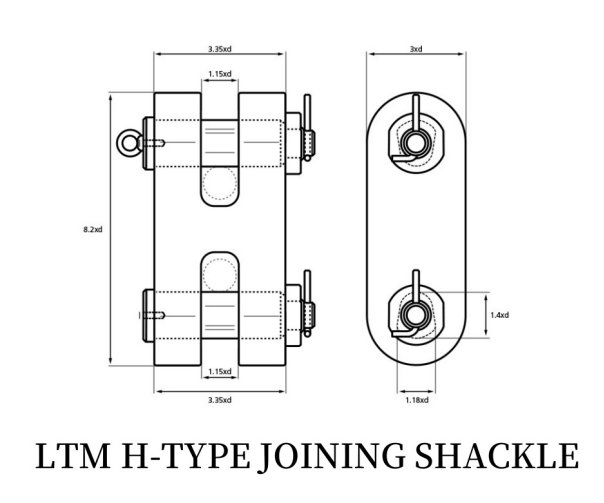

LTM H-TYPE JOINING SHACKLE(LTM HJS)

| Product Features: | |

| Application: | Kind of high-strength connectors used in mooring engineering field |

| Material: | R3/R4 Alloy steel |

| Surface finishing: | Sprayed or Hot Dipped Galvanized |

| Safety factor: | Breaking load is 4 or 6 times the rated load |

| Certifications: | DIN、EN、ISO、BV、CCS、ABS |

Description

LTM H-type joining shackle is a kind of high-strength connectors used in mooring engineering field, usually made of alloy steel or high-strength steel, with high tensile strength, wear-resistant, corrosion-resistant and other characteristics, suitable for heavy loads, harsh working conditions.

1.Structural characteristics

(1)H-shape design

The main body of the shackle is in ‘H’ shape structure, the ring eyes on both sides are symmetrically distributed, and the middle beam provides high-strength support, which makes the overall force uniform, and the tensile and shear resistance is excellent.

The inner wall of the ring eye is smooth, which reduces the wear and tear of the rope or chain and prolongs the service life.

(2)High strength material

Usually made of alloy steel (e.g. 40Cr, 42CrMo) or high-strength stainless steel (e.g. 316L), the surface is heat-treated or zinc-plated, sprayed, etc., to enhance the abrasion and corrosion resistance.

(3)Safety locking mechanism

Equipped with high-strength bolts or pins to ensure a firm connection and prevent accidental dislodgement.

2.Application Scenarios

(1)Marine Engineering

Suitable for offshore platforms, ship mooring, deep-sea operations, etc., to withstand high salt spray, high humidity environment.

(2)Energy field

In the oil, gas, electric power and other industries, it is used for lifting drilling equipment, pipelines, transformers and so on.

3.Technical Parameters

Material Alloy steel (40Cr), stainless steel (316L)

Surface treatment Heat treatment, zinc plating, spraying.

Rated load Depending on the model, the load range is from a few tonnes to hundreds of tonnes.

Safety factor Usually 4:1 or 6:1 (i.e. breaking load is 4 or 6 times the rated load).

Operating temperature -40°C to +200°C (some models can withstand higher temperatures)

Certification standards Comply with international standards such as DIN, EN, ISO, etc., and some models have been certified by classification societies such as CCS and ABS.

4.Precautions for use

(1)Selection and matching

Select the appropriate model according to the actual load, overloading is strictly prohibited.

Make sure the rated load of the shackle is greater than or equal to 1.5 times of the actual working load (considering the safety factor).

(2)Regular inspection

Check the surface of the buckles for cracks, deformation, wear and other defects before use.

Conduct regular non-destructive testing (such as magnetic particle flaw detection, ultrasonic testing) to ensure that there is no internal damage.

(3)Correct installation

Ensure that the rope or chain passes through the eye of the ring correctly and avoid twisting or knotting.

When locking bolts or pins, tighten them according to the specified torque to prevent loosening.

(4)Environmental adaptability

In corrosive environments, give preference to buckles made of stainless steel or galvanised.

Avoid using in high temperature or low temperature extreme environment beyond the range of material resistance.

5. Advantage summary

High strength and light weight: H-shape design optimises force and reduces weight.

Strong durability: high-quality materials and surface treatment, adapt to harsh working conditions.

High safety: strict compliance with international standards, equipped with safety locking device.

Wide range of applications: covering marine, energy and other fields.